Stronger, Cleaner, Longer-Lasting: The Impact of Outdoor Surface Sealing

25. November 2025

CONICA is known for delivering high-quality sealing systems across all application areas – whether for indoor sports halls, industrial floors, decorative solutions, or sports and recreational surfaces outdoors. But what specific benefits does a sealing layer actually offer in exterior applications? With this article, we aim to highlight the clear advantages that sealing provides in outdoor environments.

CONICA’s lightfast (aliphatic) seal coats not only enhance aesthetics, but also protect surfaces from UV exposure and provide excellent chemical resistance.

Advantages

- Maximum UV protection and long-term colour stability

- Increased abrasion resistance

- Improved fixation and bonding of granules

- Enhanced cleanability, as less dirt penetrates into the surface

- Reduced cleaning effort and maintenance costs

- Faster water runoff during rain

- Visible visual enhancement of the surface

- Ideal as a “face-lift” for existing running tracks – after applying a seal coat, tracks look new again and remain visually appealing for years

- Lower maintenance costs quickly offset initial installation expenses

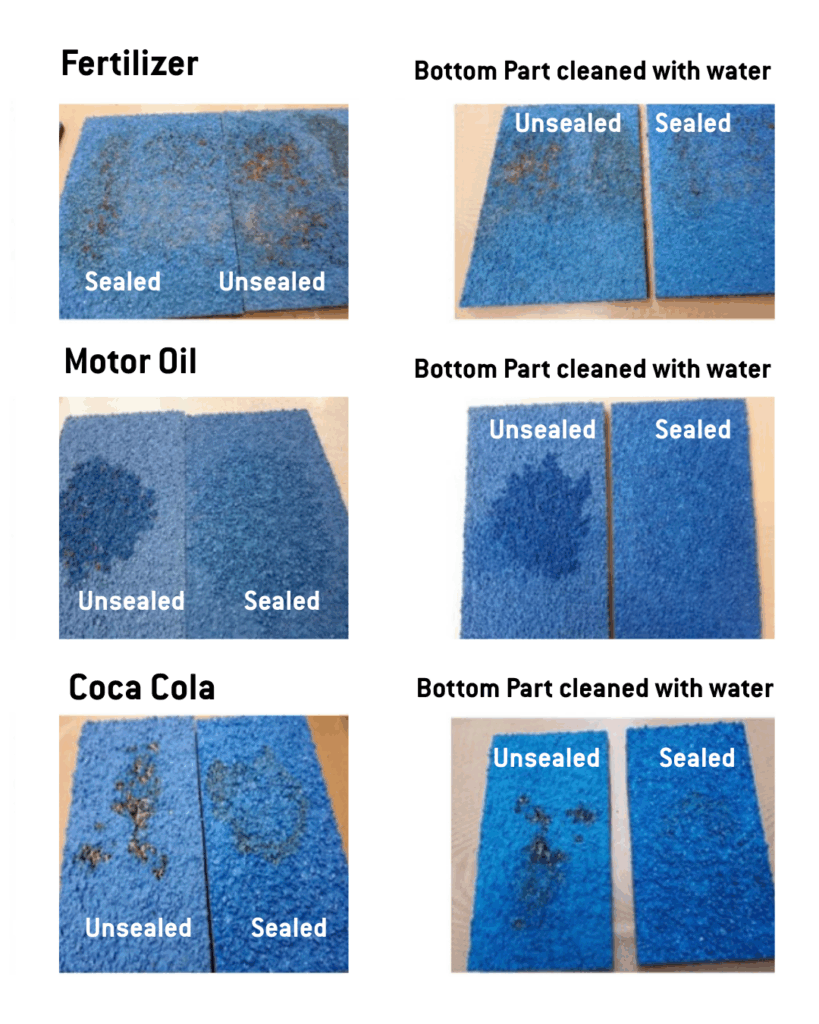

Cleaning Comparison: With and Without Seal Coat on a Broadcast EPDM Surface

Internal tests simulating typical contamination on running tracks clearly demonstrate how liquids penetrate an unsealed broadcast EPDM surface. The comparison between an unsealed sample and a sealed sample each also partially washed with water shows the significant reduction in absorption and improved cleanability achieved with sealing.

Applications

Outdoor seal coats are used in a wide variety of systems. Whether applied on structural spray coatings, broadcast EPDM surfaces, or EPDM floorings (used indoors only in exceptional cases), sealing creates added value across all application fields (see also “Outdoor Seal Coat Application”).

To meet different requirements, a range of variants and colours is available.

Variants

For outdoor use, CONICA currently offers a standard seal coat, CONIPUR 2200, and a slip-resistant version, CONIPUR 2210, designed for smooth surfaces.

Both seal coats can be customised to meet individual client needs through the following options:

- Pigmented: suitable for monochrome surfaces; available in (almost) any colour

- Colourless: ideal for multicoloured or pre-lined surfaces

- AB Version – tested according to ISO 22196:2011 (pigmented & colourless)

The antibacterial versions CONIPUR 2200 AB and CONIPUR 2210 AB reduce the risk of microbial transfer via the floor and do not provide a breeding ground for microorganisms.Keimverschleppungen über den Boden und bieten Mikroorganismen keinen Nährboden.

Durability

Durability varies depending on UV exposure and weathering, but the following general service lives can be expected:

- Pigmented seal coat: 10–15 years

- Colourless seal coat: 2–3 years

To maintain the aesthetic appearance of a sports or recreational surface, the colourless seal coat can be reapplied after 2–3 years (depending on UV exposure and weathering). Before reapplication, the surface must be thoroughly cleaned with high-pressure water. Once completely dry, the colourless seal coat can be applied without any additional preparation.

We hope this overview has demonstrated the benefits of CONICA’s outdoor seal coats as clearly to you as they have to us. For further information, please do not hesitate to contact your regional sales representative or reach out to our customer service team in Schaffhausen.