Any questions? You’ll find your answers here!

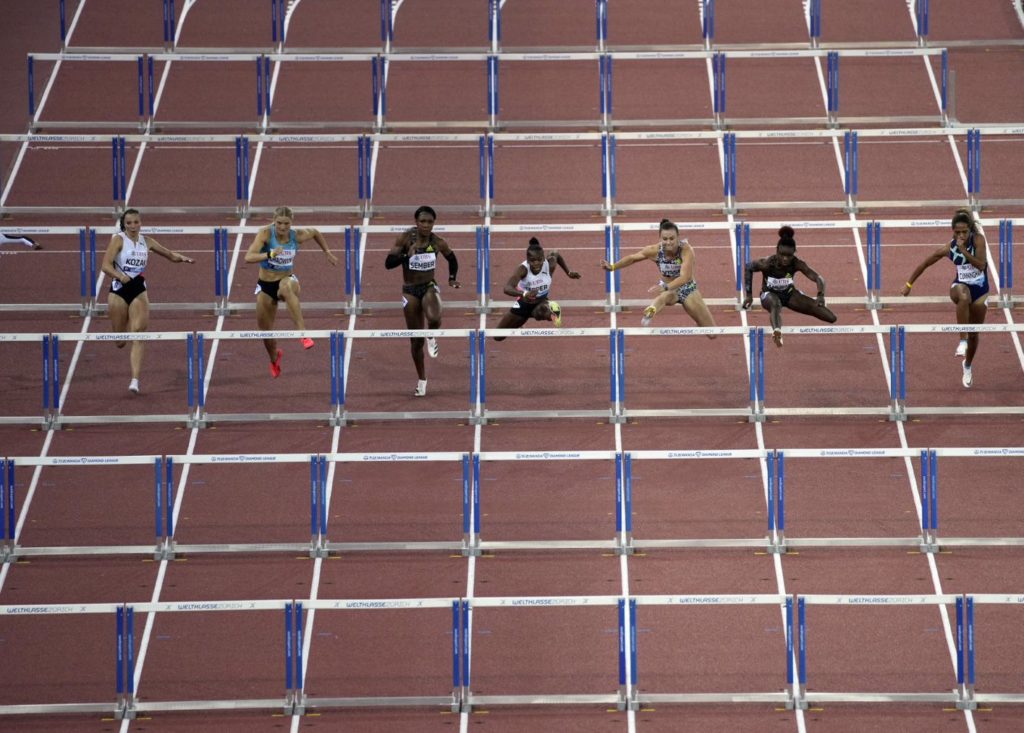

CONICA’s state-of-the-art athletic surfaces enable the athletes to reach their peak performance while reducing the risks of injury. Whether for training, top events, school sports or leisure, we care about the health of the athletes.

CONICA is taking all the steps necessary and beyond, to comply with environmental standards worldwide. None of the flooring solution – outdoor or indoor – does contain any heavy metals. Ammonia, cadmium, formaldehyde, mercury, lead, PAH or halogens are not part of our recipes and therefore our products do not contain any of these materials.

When selecting the proper athletic surface there are many factors to consider, including but not limited to:

– will the surface rather be used for training or competitions or both?

– will important competitions take place on your track

– is a World Athletics certification required?

– is there already a track in use, or will a completely new one be installed?

– which budget-range do you have in mind for the project?

Contact us, too find the right track system for you!

Yes, CONICA has installed, and is available to build athletic surfaces world-wide through our network of local distributors spread across the globe. Furthermore, our flooring solutions are suitable for almost every climate zone.

Yes, CONICA has 6 World Athletics certified surfaces (product certificates). We have a World Athletics certified surface for your every need. Thanks to the suitability test (EN 14877) the suitability and durability are proven.

When selecting a suitable athletic surface supplier there are numerous factors to consider, including but not limited to:

– client referrals and test reports

– quality of products used

– origins of the materials

– which professional organizations they belong to

– experience and “quality commitment” of the installer

– longevity and possibility of re-topping

The durability of a track surface depends on many different factors such as level of use, climate, UV-exposure, installation conditions, use of the facility (if it’s also used for events), quality of installation (has the installation been done according to the manufacturer’s instructions or were the necessary quantities reduced, were other products used etc.), maintenance (cleaning, immediate and professional repair as needed), if a was a top coat applied, etc.

Based on our experience, we estimate the durability as follows:

– Full PU surfaces (such as CONIPUR Vmax, M, MX+): approximately 20 years

– Sandwich surfaces (CONIPUR SW): approximately 10 year

– Spray coatings (CONIPUR SP): approximately 5-10 years

One great advantage is our re-topping solutions (also available for indoor floors), where the original track surface must not be completely removed. With the application of a wear layer the track can possibly be refurbished and feature again a very good sports functionality – an economic and sustainable solution.