What are the advantages of outdoor sealing?

20. December 2021

CONICA is characterised by its high-quality sealing in all areas where it is used – whether in indoor sports halls, for industrial or decorative flooring solutions, or for outdoor sports and leisure floors. But what are the advantages of sealing when used outdoors? With this article, we would like to convince you of the clear advantages also in the outdoor area.

The lightfast (aliphatic) sealers from CONICA not only look good, but they also protect surfaces from UV rays and are chemically resistant.

Advantages

- Highest level of UV protection and colour steadiness

- Increase in abrasion resistance

- Better fixation / integration of the granules

- Better cleanability, as the sealing means that less dirt penetrates the surface (see the pictures from internal tests)

- Reduced cleaning effort

- Rainwater runs off faster

- Appearance of the surface enhanced

- Suitable as a facelift for existing tracks. After a sealer has been applied, the tracks once again look like new – and stay that way for years!

With the maintenance cost savings, the initial installation costs are amortized quickly.

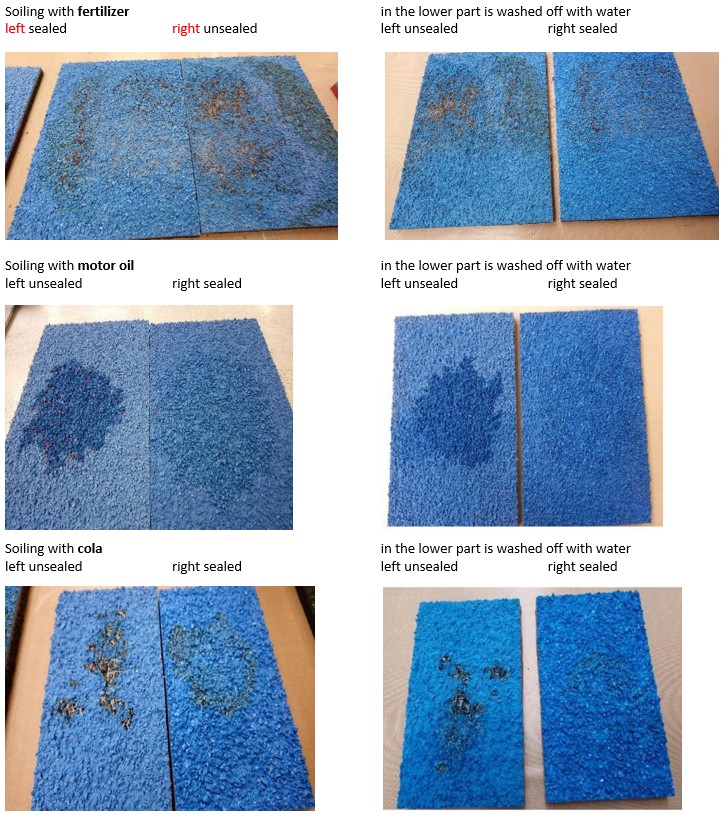

Comparison of cleaning with / without sealer on a broadcasted EPDM surfaces

Internal tests, which simulate the possible contamination of a track, illustrate how liquids can penetrate into a poured EPDM surfaces. This is done by comparing an unsealed (left) with a sealed (right) broadcasted EPDM surfaces – even when a part of the sample was washed off with water in each case.

Usage

Sealants are widely used outdoors. Whether on structural spray coatings, on EPDM broadcasted surfaces, or on EPDM surfaces (indoors only in exceptional cases), sealing leads to added value for the user in all fields of application (see also “Outdoor sealer finishing”). Accordingly, different versions and colours are available for different needs.

Variants

Conica currently offers a standard sealer, CONIPUR 2200, for outdoor use, and a slip-resistant version, CONIPUR 2210, for smooth surfaces.

Both sealers can be perfectly tailored to the customer’s needs, with the following options:

- Pigmented: can be used for monochrome coverings in (almost) all colours

- Colourless: for multi-coloured or already lined areas

- NEW: AB version tested according to ISO 22196:2011 (pigmented & colourless)

CONIPUR 2200 AB and CONIPUR 2210 AB reduce the risk of germs being carried over the ground and do not create a breeding ground for microorganisms.

Durability

Depending on the amount of sunlight exposure and weathering, the durability of the sealers differs depending on the version. However, we can forecast the following rough lifespans:

- pigmented sealer: 10 – 15 years

- colourless sealer: 2 – 3 years

In order to enhance the aesthetics of a sports or leisure floor outdoors, the colourless sealer can be reapplied after 2 – 3 years (depending on sunlight exposure and weathering). To do this, the surface must first be cleaned with high-pressure water. After the top surface has dried completely, the colourless sealer can be applied without further preparation.

We hope that you are as convinced of the quality of CONICA outdoor sealers as much as we are. For further information, please do not hesitate to contact our sales advisor for your region or our customer service in Schaffhausen.